7.1. Introduction

This section will summarise the most common construction methods for low-volume roads on peat.

Road construction in peat can essentially be sub-divided into four broad classifications:

7.2 Avoidance

7.3 Peat excavation and replacement

7.4 Peat displacement

7.5 Peat left in place

7.2. Avoidance

The simplest method of dealing with peat is to avoid it, go around it, do not cross it. This may seem obvious at first glance but it is sometimes overlooked when planning a route corridor when the design focus is on other things. But if circumstances permit (alignment, environment, economics, etc) avoiding the peat is a sensible option.

7.3. Peat Excavation and Replacement

Excavation and replacement of the peat below the road line is the safest option for constructing, or improving, a road over peat other than by avoidance. In this method, all of the weak materials under the road line are excavated out to a suitable firm layer and the embankment is constructed on the exposed sound foundation, preferably with non-cohesive material locally won on site

Where it can be used the method is a dependable way of constructing an acceptable road across peat with the minimum risk of settlement or shear failure, provided that all of the peat is excavated down to the sound load-bearing layer. In these circumstances, the bearing capacity of the new embankment will be dependent on the method and materials of construction.

Peat excavation and replacement are however only generally economic for the shallower depths of peat where excavation quantities are likely to be small. countries suggest that the economic limit for the excavation method normally lies somewhere between 3 and 4 metres of peat for public roads. The actual economic depth at a particular location will depend on the local parameters, e.g. the type of peat, the area of peat, the cost of the backfill material, availability of spoil areas, etc. (Note: Wind farm developers in Scotland currently consider the economic depth to be 1.0m to 1.5m of peat.) What can be said with some certainty is that after 4m of excavation it will become increasingly more difficult to keep the peat excavation sides stable.

The excavation method is not without its disadvantages:

- In deeper bogs, local pockets of peat can be left unexcavated. These can produce bearing capacity problems and settlements in the finished embankment where they are left in place;

- If the peat has a low shear strength, the side slopes of the excavations may become unstable and slide into the excavations before they can be backfilled. This can significantly increase the expected excavation quantities;

- Adjacent structures and buildings alongside the excavation may be adversely affected by the removal of the side support if not adequately protected;

- Suitable storage areas need to be identified locally for the disposal of the excavated peat;

- The new embankment can act as a linear drain and affect the hydrology of the area

7.4. Peat displacement

When excavation is considered unsuitable due to the depth of the peat, a displacement method may be possible, and a number of these have been used across the Northern Periphery. The most common are described next:

7.4.1 Progressive displacement

7.4.2 Partial excavation

7.4.3 Assisted displacement

7.4.1. Progressive displacement

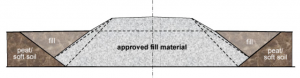

The ‘progressive displacement’, or ‘displacement’, the method is normally used where the depth of peat to be replaced is beyond the economic limit for excavation, and the weight of the intended road embankment is expected to be sufficiently heavy to displace the type of peat below. The method is suitable when the soil stratigraphy consists of peat on top of soft gyttja and clay layers. It is not however usually suitable where the soil consists of only fibrous peat as the fibres can hinder displacement, see also

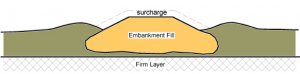

In this method, a standard embankment is constructed up to the edge of the peat deposit and then driven across the peat by end tipping, normally helped by a surcharge at the point of the advancing embankment to maximize the local displacement weight. The effect of the combined weight of the embankment and the surcharge is to cause a shear failure in the peat/soft soil ahead of the embankment, and a ‘displacement’ of the peat/soft soil to the side of the advancing embankment.

The method is normally used for the construction of wide embankments where the underlying peat/soft soil is deep and beyond the limit of economic excavation. Under these circumstances, standard progressive displacement techniques may not be fully effective due to the need to place sufficient weight across the full cross-section to achieve displacement.

The partial excavation method is particularly useful where the top layers of the peat deposit are very fibrous or woody. Where these layers exist they can act as a surface reinforcement to the peat and resist the displacing forces of the embankment. In these circumstances, the fibrous layers can be excavated out and the remaining peat displaced by the embankment assisted by a surcharge. This method has been successfully used in Finland for replacement depths of 10-12 metres.

7.4.3. Assisted displacement

Where displacement is difficult it can sometimes be assisted by water jetting or blasting to reduce the strength of the peat.

By water jetting

Water jetting involves pushing water jet lances into the base of the peat ahead of the embankment front to locally increase the water content of the peat, and reduce its shear resistance. The lances are then slowly withdrawn whilst the water is being pumped into the ground. This maximises the volume of peat treated.

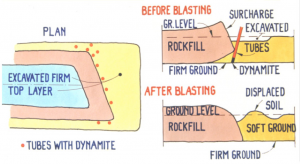

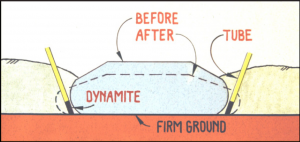

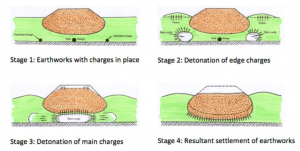

By blasting

Blast assistance to aid displacement can be carried out by a number of means:

“trench shooting”

7.5. Peat left in place

This section deals with methods that use the strength of the in-situ peat to support the weight of the new road. These methods eliminate the need to transport large quantities of fill material and are becoming increasingly more attractive to engineers as road construction budgets reduce and more cost-effective solutions are sought. Recent environmental and waste minimisation regulations also add to the arguments for using methods that build on the peat in place.

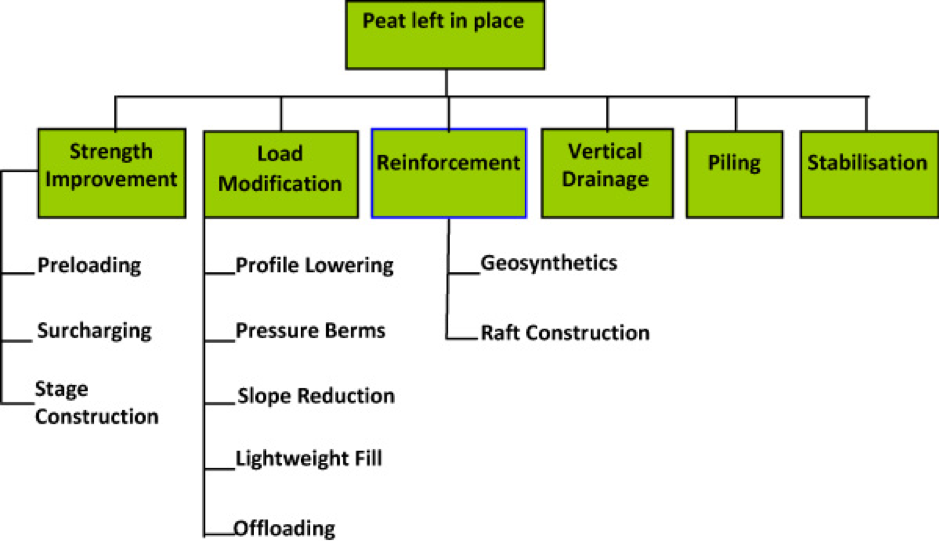

This section will look at 6 groups of methods that utilise the underlying peat as a load-bearing layer. These are:

7.5.1 Strength improvement

7.5.2 Load modification

7.5.3 Reinforcement

7.5.4 Vertical drainage

7.5.5 Piling

7.5.6 Stabilisation